Cold Mix Asphalt: Leading The Way to Lasting Infrastructure

Cold mix asphalt, with its variety of advantages for lasting framework, has actually been increasingly gaining acknowledgment in the building and construction market. The cutting-edge residential or commercial properties of cool mix asphalt not just supply toughness and environmentally friendly benefits yet likewise provide an economical remedy for different infrastructure demands. As the need for lasting methods proceeds to expand, checking out the advancements and prospective applications of chilly mix asphalt in framework development comes to be critical for a future that prioritizes reliable and environmentally conscious building and construction techniques.

Benefits of Cold Mix Asphalt

Enhancing road durability and minimizing environmental effect are vital advantages of utilizing cool mix asphalt in infrastructure jobs. Cold mix asphalt is a lasting alternative to traditional warm mix asphalt as a result of its lower manufacturing temperatures, which cause minimized energy usage and reduced greenhouse gas emissions.

One of the main benefits of cool mix asphalt is its flexibility in application. It can be made use of in numerous weather problems, making it ideal for year-round building and construction tasks. Additionally, chilly mix asphalt can be accumulated for future use, permitting versatility in job planning and execution.

Furthermore, using chilly mix asphalt adds to set you back savings over the life expectancy of a roadway. Its toughness and capacity to withstand hefty traffic tons result in less fixings and maintenance requirements, inevitably minimizing the overall life process prices of the framework.

Ecological Effect

With a focus on sustainability and lowering carbon impacts, the environmental influence of carrying out cold mix asphalt in facilities jobs is a crucial facet to think about. Cold mix asphalt offers considerable ecological benefits contrasted to hot mix asphalt.

Additionally, making use of chilly mix asphalt can result in decreased waste generation. Conventional warm mix asphalt production frequently leads to excess product that goes extra, adding to land fill waste. Cold mix asphalt, on the other hand, can be stockpiled for later use without the risk of product deterioration, decreasing waste and promoting a much more lasting technique to infrastructure advancement.

On top of that, cool mix asphalt is more eco-friendly during application. Its lower production temperature levels minimize fumes and emissions at the worksite, enhancing air high quality and developing a more secure working setting for construction crews. Generally, the environmental impact of cold mix asphalt demonstrates its possible to lead the way towards greener and a lot more sustainable infrastructure practices.

Cost-Effectiveness

The cost-effectiveness of carrying out cool mix asphalt in facilities tasks is a key consideration for stakeholders seeking sustainable and efficient solutions. Cold mix asphalt provides numerous expense benefits over traditional warm mix asphalt, making it an appealing choice for different applications. One of the primary cost advantages of cool mix asphalt is its lower production temperature level demand, which results in reduced power intake during manufacturing. This not only lowers manufacturing expenses yet also adds to lower greenhouse gas exhausts, straightening with sustainability goals. find out here

Additionally, cool mix asphalt calls for less customized devices for its application compared to hot mix asphalt, resulting in lower resources investment for building and construction companies. On the whole, the cost-effectiveness of cold mix asphalt makes it a financially sensible choice for framework jobs aiming for sustainability and effectiveness.

Applications in Framework

Cold mix asphalt is commonly used for fixing gaps, filling holes in roadways, and patching damaged asphalt surfaces. In addition, chilly mix asphalt is used in remote locations where warm mix plants are not quickly available, making it possible for infrastructure growth in formerly hard-to-reach areas. In general, the varied applications of cool mix asphalt emphasize its relevance in promoting lasting infrastructure development.

Future Leads

In light of recurring improvements click to read more in building and construction innovation and sustainable practices, the future leads for cold mix asphalt appear encouraging. The constant advancement of chilly mix asphalt formulations is expected to enhance its performance attributes, making it a more affordable and resilient solution for different facilities tasks. With a growing focus on environmentally pleasant building materials, cold mix asphalt is most likely to acquire more grip in the market as a result of its lower carbon footprint contrasted to hot mix asphalt.

Furthermore, the versatility of cold mix asphalt in regards to application techniques and suitability for a vast array of climate condition positions it as a beneficial choice for future infrastructure growths - Asphalt Patch Repair. As research and advancement in the area progress, the potential other for integrating recycled products right into cold mix asphalt blends can further strengthen its sustainability credentials

Final Thought

In conclusion, chilly mix asphalt offers a sustainable and cost-efficient solution for facilities projects. Its benefits, including boosted road long life, decreased environmental impact, and versatile applications, make it an optimal option for both emergency repair services and lasting maintenance. As advancement and innovation in cold mix asphalt formulations proceed to proceed, the future holds encouraging leads for extra eco friendly and efficient facilities solutions.

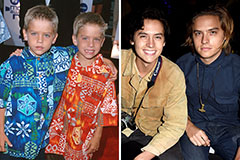

Dylan and Cole Sprouse Then & Now!

Dylan and Cole Sprouse Then & Now! Amanda Bearse Then & Now!

Amanda Bearse Then & Now! Julia Stiles Then & Now!

Julia Stiles Then & Now! Mason Reese Then & Now!

Mason Reese Then & Now! The Olsen Twins Then & Now!

The Olsen Twins Then & Now!